Polyacrylamide polymers play a vital role in oil field recovery. The recovery rate of the oilfield can be effectively improved through the reasonable application of polyacrylamide polymer.

The main application principles of polyacrylamide polymers in oilfield recovery enhancement are analyzed to ensure the effectiveness of polyacrylamide polymers and meet the actual efficiency needs of today’s oilfield companies.

This includes an overview of polyacrylamide polymers, an analysis of the main mechanisms of polyacrylamide polymers for oilfield recovery enhancement, and an analysis of the main development trends of polyacrylamide polymers in oilfield extraction.

Keywords: oil field extraction; polyacrylamide polymer; recovery.

In oilfield extraction by polyacrylamide, the physical and chemical characteristics of polyacrylamide and its application conditions in oilfields should be clarified by oilfield companies, researchers, and technicians to achieve further improvement of recovery rate. Then, the main principle of its role in oilfield recovery improvement should be analyzed. At the same time, the main trends of polyacrylamide should be analyzed in light of the actual situation and needs of today’s oilfield.

This way, polyacrylamides can be used in oilfield production to achieve the full advantage of oil drive. In this way, the efficiency of modern oil fields can be ensured. To further meet the needs of today’s society for oil applications. To promote the good operation and development of oilfield enterprises.

1. Overview of polyacrylamide.

1.1 Introduction of polyacrylamide.

Polyacrylamide is a water-soluble polymer formed by the homopolymerization of acrylamide or copolymerization with other monomers. Because of the presence of amide groups in its structural units and the easy formation of hydrogen bonds, polyacrylamide has good water solubility. It is also highly chemically active.

Polyacrylamide can achieve a wide range of modified products with reticulation or branched structures with cross-linking or grafting. These modifications can be used as auxiliaries in agriculture, medicine, mining, paper, textile, water treatment, and oil extraction.

They have been widely used in many fields, especially oil extraction, where polyacrylamide is vital in oil repelling.

1.2 Analysis of the physical and chemical properties of polyacrylamide.

At room temperature, polyacrylamide is white granules or powder; at high temperatures, polyacrylamide will appear glassy, softening, thermal decomposition, etc. Fully dried polyacrylamide will appear as a white solid with a certain brittleness.

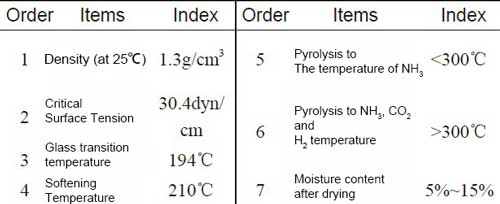

In water, polyacrylamide is very easy to dissolve. The pH of the water, the temperature difference, and the stirring time have a direct influence on the solubility. In many organic solvents, polyacrylamide is insoluble. Even if dissolved, the degree of dissolution is very limited. It is only partially soluble when heated. Table 1 shows the main physical properties of polyacrylamides.

Table 1 Main physical property parameters of polyacrylamide.

Polyacrylamide polymers are capable of many chemical reactions because the amide groups in the side groups of the molecular bonds are very reactive.

1.3 Reservoir conditions to which polyacrylamide is applicable.

The application of polyacrylamide can significantly enhance the recovery of oil in the oil recovery process. However, polyacrylamide is unsuitable in all reservoir conditions due to its physical and chemical properties. At present, polyacrylamide is suitable for the following reservoir conditions.

First, for non-homogeneous reservoirs, the influence of non-homogeneous formations requires a certain permeability coefficient of variation. It has been found that polyacrylamide can have a good oil drive effect when the coefficient of variation in the reservoir is below 0.7.

Secondly, the chemical activity of polyacrylamide is very high, and heat can easily decompose it. Therefore, polyacrylamide may also degrade in some deeper reservoirs due to increased temperature and water mineralization. Current research cannot scientifically establish the relationship between formation temperature and depth. However, it is generally believed that polyacrylamide can only be effective in oil drive when the formation temperature is 70℃ and below.

Thirdly, in the process of oil repelling by polyacrylamide, the viscosity of crude oil will also greatly influence its oil-repelling effect. If the crude oil has a higher viscosity, its permeability resistance will be higher, and the replacement pressure difference in oil repelling will be increased. This can significantly improve the oil-repelling effect of polyacrylamide.

If the crude oil is not viscous enough, the recovery rate of the water drive will be increased. As a result, polyacrylamide can not play a significant oil drive effect. Based on this, in the specific oil recovery process, oil recovery companies must also reasonably determine the range of crude oil viscosity in the reservoir. When the crude oil viscosity is sufficient, the polyacrylamide plays a good oil-repelling effect.

Fourthly, polyacrylamide’s injection viscosity and injection speed also greatly influence the oil-repelling effect. The greater the injection viscosity and the faster the injection speed of polyacrylamide polymer, the better the oil-repelling effect and the longer the duration of action (usually lasting for several years).

2. Analysis of the main principles of polyacrylamide to improve oilfield recovery.

2.1 Oilfield recovery enhancement through flow ratio optimization.

In the oilfield extraction process, an important mechanism to enhance its recovery by polyacrylamide is to reduce the water phase flow ratio. However, water ingress is usually severe when water drive is applied to reservoirs in non-homogeneous formations. This is because the geology of inhomogeneous formations is very complex, which harms the effect of water drive in oil fields.

By injecting water containing polyacrylamide into the reservoir, the adverse effects of inhomogeneous formations on the drive can be significantly reduced, resulting in a good improvement of the plane wave and a further increase in the drive efficiency the oilfield.

For reservoirs in non-homogeneous vertical formations, when polyacrylamide solution is injected into the formation, it will first “plug” the high permeability layer. This allows the water drive to move smoothly into the lower permeability layers and continue the drive.

In this process, the high viscosity of polyacrylamide solution can increase the wave volume and improve the oil drive efficiency.

In homogeneous formations, the effect of the water drive can be adversely affected to a certain extent because of the difference between the viscosity of the injected water and the original viscosity. In such cases, water containing polyacrylamide can be injected to make the injection water more viscous. This results in an effective reduction of the water-phase permeability. The increase in water content in the oilfield can be delayed. This enhances the replacement effect of the oil field and improves the recovery rate.

2.2 Improving oilfield recovery through viscous effects.

After injecting the oil-repellent water containing polyacrylamide into the oilfield formation, the viscosity of the water phase can be increased by the viscoelastic effect of polyacrylamide. This reduces the permeability in the formation. This can effectively reduce the frictional resistance in the oil phase percolation process and achieve a good oil-repelling effect.

In the flow channel, the polyacrylamide solution molecules can “fill” or “stretch” the depressions in the pipeline. This eliminates the “Haines jumps” (capillary network formed by multiple pores, which makes the pore cross-section extremely unbalanced and has an irregular seepage effect) in the pore crevices. In such a case, the residual oil inside the pore channel will be piston-like in its propulsion, thus allowing a significant increase in crude oil recovery at the microscopic level.

2.3 Enhanced oilfield recovery by adsorption.

In the reservoir channel, the polyacrylamide solution will adsorb to a large extent to the pore surface as it passes through. In this case, the polyacrylamide will adsorb to the pore surface, thus sealing the water in the pore space without affecting the oil flow. This adsorption results in lower permeability and higher permeability resistance and driving pressure differential in the pore medium during oil recovery. In this way, the oil reservoir can have a larger wave volume, thus further increasing field recovery.

3. Analysis of the main development trends of polyacrylamide in oilfield extraction.

Polyacrylamide should also develop in a more advanced direction to adapt to the actual work requirements of today’s oilfield mining and enhance the oilfield recovery rate. The main development trend of polyacrylamide in the current oilfield mining technology and its development includes two aspects. The first is to improve salt and high-temperature resistance further, and the second is to develop in the direction of ultra-high relative molecular weight.

3.1 Improved salt resistance and high-temperature resistance.

The common form of polyacrylamide can be a good promoter for oilfield recovery, and its application value is relatively good. However, polyacrylamide still has limitations in terms of practical application. There are two typical limitations. First, the common form of polyacrylamide does not have sufficient salt resistance. The second is that the common form of polyacrylamide does not have a high enough resistance to high temperatures.

In such cases, the polyacrylamide will be prone to adverse changes, which will adversely affect the application effect and lead to the failure of oilfield recovery to achieve the desired efficiency.

For this reason, many researchers have started to develop and improve the common forms of polyacrylamides. They injected some structures or groups with good salt and high-temperature resistance into polyacrylamides, thus making new polyacrylamides with better salt and high-temperature resistance. For example, the injection of R-SO3H into the polyacrylamide resulted in a new polyacrylamide with improved salt and high-temperature resistance. This new polyacrylamide is also called salt and high-temperature resistant polyacrylamide.

However, today, new polyacrylamides in the form of salt and high-temperature resistance are still not widely used in oil field extraction. This is because the number of structures or moieties used in them is still relatively scarce. These real problems need to be solved by further research.

But since the emergence of these new polyacrylamides, polyacrylamides have also gained a whole new way of thinking and development in the field of oilfield extraction. Since the salt resistance and high-temperature resistance can be improved through structure or group injection, other limitations of polyacrylamide can be further improved by structure or group injection.

For example, the hydrolysis resistance of polyacrylamide can be improved by injecting certain structures or groups. This will not only promote the further development of the polyacrylamide production process and its application performance but also help improve the oil field’s recovery rate.

3.2 The development of ultra-high relative molecular weight direction.

Ultra-high relative molecular weight means that it has a large molecular weight. If polyacrylamide has this characteristic, its viscosity will become very high. It is not easy to lose viscosity under the influence of various factors. Therefore, such polyacrylamide will have a stronger viscosity effect and a better adsorption effect. Therefore, the application of polyacrylamide in oilfield extraction will lead to a significant increase in oilfield recovery.

At the same time, if polyacrylamide has a high relative molecular weight, its shear resistance will be better. This makes it more effective in dealing with the “Haynes jump” phenomenon. The stability is also very strong. Even under certain dimensional conditions, if the polyacrylamide has a very high relative molecular weight, the viscosity reduction becomes very small, and the stability improves.

For this reason, more and more researchers have started to study this polyacrylamide, and some research results have been obtained. At present, polyacrylamide with very high relative molecular weight has been developed. They have been applied in the Daqing oil field in China.

The new polyacrylamide with ultra-high relative molecular weight can significantly improve the oil field’s recovery rate. Compared with the common form of polyacrylamide, the recovery rate can be increased by about 20%.

4. Conclusion.

Polyacrylamide is one of the main oil repellents in the oil field. Therefore, when polyacrylamide solution is injected into the reservoir formation, it can give full play to its oil-repelling effect. Thus, the recovery rate of the oil field can be significantly improved.

Based on this, oilfield companies, researchers, and technicians should pay full attention to the mechanism of polyacrylamide in oilfield exploitation. Based on this, polyacrylamide should be reasonably applied. At the same time, further research and improvement are needed to make it have better oil-repellent advantages based on the original one.