What are the Drag Reducing Agent (DRA) Functions?

Drag Reducing Agent (DRA) is used in crude oil and refined product pipelines to increase the flow rate or reduce the required pressure for a certain flow rate (pumping energy consumption). Pipeline capacity can be increased instantly. Pumping energy consumption also can be reduced quickly from 40% to 60% by adding our DRA on ppm level into a pipeline.

Active Ingredient in DRA

The active ingredient in Drag Reducer is an ultra-high molecular weight Poly Alpha Olefin (PAO). The general chemical formula is shown in the figure below. R indicates carbon chains of various lengths. N specifies how many times the unit in parenthesis is repeated. It is around 100,000. The MW of drag reducer agent is about tens of millions.

The Mechanism of Drag Reducing Agent (DRA)

When the drag reducer dissolves in crude oil, polymer molecules begin to uncoil and outspread as they interact with the pipeline flow. The long-chain molecules can dampen turbulent bursts near the pipe wall as tiny shock buffers. This dampening effect and frictional pressure loss will bring a decrease in energy consumption or an increase in flow rate.

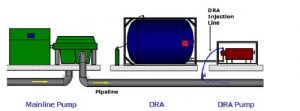

A Typical Drag Reducing Agent Injection Operation

Drag Reducing Agent is usually injected into pipelines at the discharge side of the main pipeline pump (see figure below). A positive displacement pump with higher pressure than the main pipeline is used to inject DRA. Drag reduction will begin once this polymer begins to dissolve in oil. DRA will not dissolve completely before several miles traveling downstream the pipeline.

When dissolved DRA chemical polymer passing through the main pipeline pump, it will be broken down or sheared. Sheared drag reducing agent polymer will perform little or no drag-reducing effect. Low-level polymer shear also occurs in some other occasions, like dissolved polymer is subjected to the natural shear forces of turbulent flow in a pipeline. A multi-station pipeline needs Drag Reducer injection points beside each mainline pump in order to achieve complete output increase.

What Innovations IRO Made?

IRO has been endeavoring to satisfy customers better by improving products and services. Compared with those DRA from other companies, ours are featured with the following advantages:

-Patented polymerization techniques and facilities have been developed and employed in production. This enables IRO to handle very high MW Alfa Olefins, which are the first step to produce more potent DRA products.

-Specialty Polymers are manufactured from Poly Alpha Olefin (PAO) with very high MW. Better drag reduction performance is already proven in these Speciality Polymers, both in the loop and industrial pipelines.

-Patented post-processing technique is utilized in DRA production, thus achieving more stable physical properties, and being easier in handling at injection sites – lower viscosity, higher homogeneity, and better pump ability.

-IRO has developed out a universal product series suitable for all fluids in which DRA is soluble, no matter what the fluids are, including crude oils, refined products, etc.

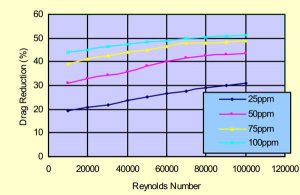

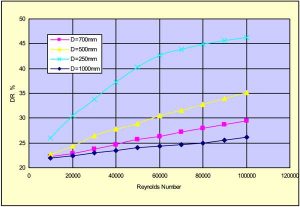

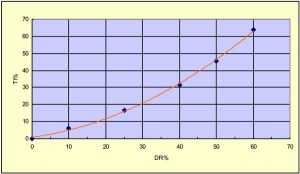

Charts Demonstrating Typical Outputs of the Loop Evaluation and Quality Control.

Chart 1: Chart reductions at various dosages.

Chart 2: The drag-reducing effects in pipes with various diameters.

Chart 3: DR% and TI% Relationship.

Click here for the Latest DRA Application Cases.