Content Table:

At present, there are many types of drag reducing agents, and the mechanism and effect of drag reduction are also different. Among them, polyethylene oxide is widely used in practical engineering applications because of its excellent performance in drag reduction and energy-saving, stability, and easy access. This post will explain the current main applications of polyethylene oxide.

1. The Application of Polyethylene Oxide in Oil Production and Mining

With the rapid development of the petroleum industry, the year-on-year increase in the demand for crude oil has reversed the rise in the volume of extraction. There are nearly 51,000 oil and gas wells in the world today. Energy-saving technology has brought huge benefits to big oil production projects. In the process of oil and gas exploitation, adding polyethylene oxide to the drilling mud has the following three points.

(1) It has obvious thickening and lubricating effect on mud, which is convenient for flow transportation.

(2) Improve the quality of the mud and prevent the wall from being damaged by acid or biological erosion.

(3) Effectively control the loss of some valuable fluids at the interface of the drilling wall and the blockage caused by the penetration of the injection fluid into the oil layer, thereby increasing the single well oil production.

In the mining industry, polyethylene oxide is mostly used in ore washing and mineral flotation. Adding a low concentration of polyethylene oxide during coal washing can quickly and efficiently deposit suspended matter. The flocculant can also be recycled repeatedly. In the hydrometallurgical process, the addition of high molecular weight polyethylene oxide helps to separate the clay material from flocculation. For example, activated clay, kaolin, etc. In the process of metal purification, the dissolved silica can also be effectively removed. Polyethylene oxide and mineral surface complexation occur. This helps to wet the mineral surface and improve the lubricity and fluidity of the mineral.

2. The Application of Polyethylene Oxide in Shale Gas Exploitation

At present, China’s shale gas exploration and mining technology have already systematized. The proved reserves reach 920 billion m3. The output is 9 billion m3. In 2020, the output will exceed 30 billion m3, accounting for about 15% of China’s total natural gas output. Shale gas production is expected to reach 80 to 100 billion m3 in 2030. Provide an important guarantee for China’s natural gas energy.

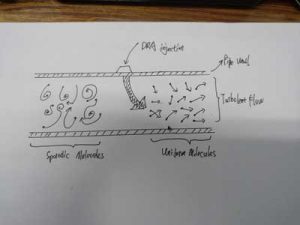

In the exploitation of tight shale gas, fracturing is the main technical means used to improve the reservoir conductivity and stimulation. When the fracturing fluid is pressurized by the high-pressure pump and injected into the formation through the pipe string, serious turbulence will occur in the pipe. This will cause huge friction between the fracturing fluid and the pipe wall.

In order to reduce the resistance when fracturing fluid is injected into the formation and increase the flow rate. Polyethylene oxide is often used as a drag-reducing agent in the fracturing fluid. It plays a significant role in reducing energy consumption in transportation. In shale gas fracturing operations, the large displacement pump has a high shear rate of the fluid, and the polyethylene oxide molecular chain is vulnerable to damage, which reduces the drag reduction ability.

At present, the main use is to add guar into the polyethylene oxide dispersion to inhibit the degradation of the composite drag dispersant. The drag reduction rate can be increased by about 24%. Suppliers configure and optimize fracturing fluids based on common formation conditions. In the end, a composite drag-reducing agent with good temperature resistance and little influence on salinity is selected, which can effectively realize the reuse of fracturing fluid.

3. The Application of Polyethylene Oxide in the Paper-making Industry

When making paper for printing, adding polyethylene oxide can be used for retention and filtration. Polyethylene oxide can form a network by bridging and bonding. With the suspended solids present in the pulp, it shows excellent retention effect.

Secondly, in order to solve the problem that pigments, fine fibers, etc. are lost during the printing process, adding a small amount of polyethylene oxide can suppress this loss and increase the retention rate. The flocculation of polyethylene oxide has a synergistic effect on the flocculant. It can speed up the paper drying speed. Reduce the deposition of resin on paper and reduce the concentration of “white water”.

Polyethylene oxide resin is also used as a long fiber dispersant in the papermaking process. To reduce the beating degree and shorten the beating time. And polyethylene oxide can form a layer of hydrated film on the surface of the pulp material to prevent the pulp fibers from settling too fast and reduce flocculation (when the amount of polyethylene oxide is 0.2%, the dispersion effect of the pulp is best). By adding polyethylene oxide, it is possible to make paper with excellent uniformity from pulp with a lower beating degree. And the softness, absorption capacity, and strength of the paper will be improved with the amount of polyethylene oxide.

4. The Application of Polyethylene Oxide in Municipal Construction

Polyethylene oxide is also widely used in municipal infrastructure. For example, in the fire water system, only a small amount of polyethylene oxide can be added to reduce the friction resistance of the firewater transportation process by 80%. Such drag reduction performance is more conducive to the fire fighting of long-distance objects and high-rise buildings.

In the face of severe urban waterlogging caused by abnormally heavy rainstorms, in order to increase the drainage volume and drainage speed of the underground pipe network drainage system, it is often added to the drainage system at the waterlogging point to the appropriate amount of polyethylene oxide to reduce the water in the drainage pipe Flow resistance. The drainage volume can exceed twice the original drainage volume, which greatly improves the drainage efficiency. It saves the cost of the transformation of the underground pipe network system and is easy to degrade without toxicity.

Conclusion

In addition to the above applications, polyethylene oxide can also be used in medical applications. Polyethylene oxide is used for drag reduction of mud during drilling and production of oil wells. IRO DRA is used to reduce resistance during the transportation of crude oil to the refinery after oil extraction. Although they are both drag reducing agents, there are differences. Please leave us a message if necessary. Thank you for reading.