Carboxymethyl Cellulose (CMC)

Oil Drilling Grade

CAS NO.:

9000-11-7

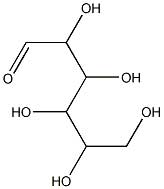

Molecular Formula:

C6H12O6

Structure Formula:

Properties:

Carboxymethyl cellulose (CMC) is a cellulose derivative obtained by chemically modificating the natural cellulose. CMC is one of the most important water-soluble polymers with many advantages that other natural or synthetic glues do not have. Carboxymethyl cellulose is white and flowing fine powder.

CMC is tasteless, smelless, mold-proof, non-toxic, non-flammable, and easily dissolved in water to become a transparent viscose solution. Carboxymethyl cellulose solution has good thickening, adhering, emulsifying, and stabilizing properties. Membrane forming, moisture-holding, shape-holding, dispersing, and anti-enzyme. The solution of CMC can be mixed with dissolvable animal glues, glycerin, sorbitol, Arabic gum, pectin, xanthic gum, and dissolvable starch.

Natural cellulose is the most widely distributed and abundant polysaccharide in nature. At present, the modification technologies of cellulose mainly focus on etherification and esterification. Carboxymethylation is one of the etherification technologies. Carboxymethyl cellulose (CMC) is one of the most important cellulose ethers obtained by carboxymethylation of cellulose. Its aqueous solution has the functions of thickening, film-forming, bonding, water retention, colloid protection, emulsification, and suspension. It is widely used in the petroleum, food, medicine, textile, and paper industries.

Specifications:

Physical specification of CMC for Oil drilling liquids & Oil drilling liquids properties (According to SY5093-92).

| LV-CMC | MV-CMC | HV-CMC | |

|---|---|---|---|

| Appearance | White or light yellow powder, freely flowable | ||

| Water, % | 10 Max. | 10 Max. | 10 Max. |

| CMC, % | 80.0 Min. | 85.0 Min. | 95 Min. |

| Substitution degree, % | 0.80 Min. | 0.65 Min. | 0.80 Min. |

| pH Value | 7.0-9.0 | 7.0-9.0 | 6.5-8.0 |

| Type | Item | Typical measured values | |||

|---|---|---|---|---|---|

| Distilled water | Brine | Saturated brine | |||

| Base mud | Filtration loss, ml | 60±10 | 90±10 | 100±10 | |

| Apparent viscosity, mPa•s | 6.0 Max. | 6.0 Max. | 10 Max. | ||

| pH Value | 8.0±1.0 | 8.0±1.0 | 7.5±1.0 | ||

| HV-CMC | Mud generating capacity, m3/t | 200 Min . | 150 Min. | 160 Min. | |

| LV-CMC | Filtration loss = 10ml | Addition rate, g/l | -- | 7.0 Max. | 10.0 Max. |

| Apparent viscosity, mPa.s | -- | 4.0 Max. | 6.0 Max. | ||

| MV-CMC | Addition rate,g/l | 6.0 | 14.0 | 3.5 | |

| Apparent viscosity, mPa.s | 15 Min. | 15 Min. | 15 Min. | ||

| Filtration loss,ml | 9 Max. | 9 Max. | 9 Max. | ||

Technical Specification of CMC for oil drilling liquids (According to GB/T5005-2001 or API).

| Type | Specification | ||

|---|---|---|---|

| CMC-HVT | Viscometer, 600r/min | Distilled water | 30.0 Min. |

| 40g/dm3 brine | 30.0 Min. | ||

| Saturated brine | 30.0 Min. | ||

| Filtration Loss (ml) | 10.0 Max. | ||

| CMC-LVT | Viscometer, 600r/min | 90.0 Max. | |

| Filtration Loss (ml) | 10.0 Max. | ||

Note: We could arrange a product according to the customer’s specifications.

Uses:

Carboxymethyl cellulose oil drilling grade is used in fracturing, drilling, and well-cementing fluid as a fluid loss controller and tackifier. CMC can protect the shaft wall and prevent mud loss, thus enhancing recovery efficiency. Carboxymethyl cellulose has the following characteristics.

- The mud containing CMC can make the good wall form a thin, firm filter cake with low permeability, reducing water loss.

- After adding CMC into the mud, the drilling rig can obtain low initial shear force so that the mud can easily release the gas wrapped in it, and the debris is quickly discarded in the mud pit.

- Drilling mud, like other suspension dispersions, has a certain period of existence, and adding CMC can stabilize it and prolong its existence.

- Mud containing CMC is rarely affected by mold, so it is not necessary to maintain a high pH value and use preservatives.

- CMC is the treating agent of drilling mud and well-flushing fluid, which can resist the pollution of various soluble salts.

- The mud containing CMC is stable and can reduce water loss even if the temperature exceeds 150 ℃.

CMC with high viscosity and a high degree of substitution is suitable for low-density mud. In contrast, CMC with low viscosity and a high degree of substitution is ideal for high-density mud. The selection of CMC shall be determined according to the mud type, area, well depth, and other conditions.

Packing and Storage:

Packed in multiply paper bags or fiber drums (25kg) or as per customer’s requirement.

Keep dry.

Synonyms:

CM-Cellulose, Carboxymethyl cellulose Ether, Carboxy Methylated Cellulose, Carmellose, Croscarmellose.

Note:

You can click here to get more details about Sodium Carboxymethyl Cellulose Formula.